HEKLA® is the first mass-produced material manufactured by Poalgi. Thirty years of experience have led to the creation of this material of extraordinary qualities, born to stand the test of time.

Inspired by the strength of volcanoes to offer the best performance in the epicentre of the kitchen, the sink; the result of a research and development project led by our ambitious team and backed by the AIDIMME Technological Institute.

Granite is one of the hardest natural stones and the main component of HEKLA® . Resistant to all external factors, it will be the best culinary companion. A companion that provides the necessary comfort and safety to create a comfortable working area in the kitchen.

Whether in classic, rustic kitchens or modern, daring kitchens, HEKLA® will be the perfect partner. The different shapes and sizes offered by the Kobus, Zie and Gandia collections will allow you to choose the sink that best suits the style and design of your kitchen.

Granite is the main component and is subjected to a thermal process that integrates the colour of the sink into every particle. The result is a homogeneous load with excellent qualities thanks to an optimised mineral, in addition to the high-quality resin incorporated in its composition. This combination produces sinks that are resistant to all external influences and guarantees excellent resistance to hydrolysis and ageing. In addition, the possibility of bacterial growth is eliminated thanks to the vacuum process through which the mixture passes before being poured into the mould. This treatment eliminates all air molecules and turns HEKLA® into a dense, non-porous mass that guarantees high strength.

Once the mass enters the mould, it undergoes a hardening process thanks to the thermal reaction that is generated. The gradual hardening of the mass results in mass sinks designed to offer the best performance in your everyday kitchen.

Roc Stone® is a material designed for comfort and versatility. A self-made material designed for the creation of sinks of exceptional quality.

The surface of these sinks is formulated with a sanitary Gel Coat, commonly used in the naval and aviation industry. This compact layer gives a great final finish and resistance to UV rays and hydrolysis.

Its composition of mineral fillers agglutinated with high quality technical resins is the result of a research process certified by AENOR. Roc Stone resin sinks offer exceptional performance compared to other materials on the market. Its resistance to scratches, knocks and high temperatures is combined with certified antibacterial properties to make the sink the best kitchen helper.

This material also allows the personalisation of the colour thanks to our Colorplus system, which makes it possible to create a unique sink. For the most modern and original kitchens, Roc Stone® sinks are the perfect choice.

The variety of shapes, sizes and design possibilities offered by the Zie, Gandia, Shira, City, Kuma and Basic collections will allow you to choose the sink that best suits your kitchen.

Roc Stone® sinks are resin sinks whose formula has been improved during thirty years of experience in the manufacture of synthetic sinks to bring the best quality to your kitchen.

The sanitary Gel Coat layer that covers the surface of these sinks provides high technical and antibacterial properties. The Gel Coat is sprayed onto the mould as the first manufacturing step and is a differentiating element compared to other products on the market.

The solid surface material is the result of using the latest technology and the highest quality raw materials. Composed of 2/3 natural minerals and 1/3 acrylic resin, Corian® is resistant, homogeneous and hygienic, mass-produced.

The solid surface material is the result of using the latest technology and the highest quality raw materials. Composed of 2/3 natural minerals and 1/3 acrylic resin, Corian® is resistant, homogeneous and hygienic.

Mass-produced, it has no visible pores or joints. This creates an aesthetic and functional continuity that sets it apart from other materials. In addition, the non-permeability of Corian® makes it highly hygienic and stain resistant, allowing for easy cleaning and maintenance.

Its strength and stability make it a highly resistant material, resistant to physical and chemical agents. A state-of-the-art, mass-produced material with a quality that stands the test of time.

its low maintenance requirements are combined with its ability to regenerate. It is an easily repairable material, always maintaining its appearance and properties as the first day. In addition, it is GREEN GUARD Indoor AirQuality Certified® for its low VOC emissions.

Corian® comes to the bathroom with unique designs with a minimalist air. The Kami freestanding bathtub and the Ashi shower tray will be the perfect space for your care. And the Kubi and Mune washbasin collections will become the essential complement.

Corian® is a solid, non-porous and homogeneous material composed of 1/3 acrylic resin (polymethyl methacrylate or PMMA) and 2/3 natural minerals. These minerals are composed of aluminium trihydrate (ATH), a derivative of bauxite.

Corian® is fabricated in both sheets and preformed parts. The solid surface is obtained by mixing the minerals and resin. In the case of the sheets, the mixture is poured onto a moving steel belt that passes through a cooling tunnel. Once the mixture has cooled, the edges of the sheet are trimmed. This first production system is used for the production of shower trays. On the other hand, in the case of pre-formed parts such as washbasins and bathtubs, the mixture is poured into moulds for production.

when a Corian® sheet is cut, the cross-section shows a uniform colour. The solid surface particles are evenly distributed throughout the structure, resulting in a solid, solid material.

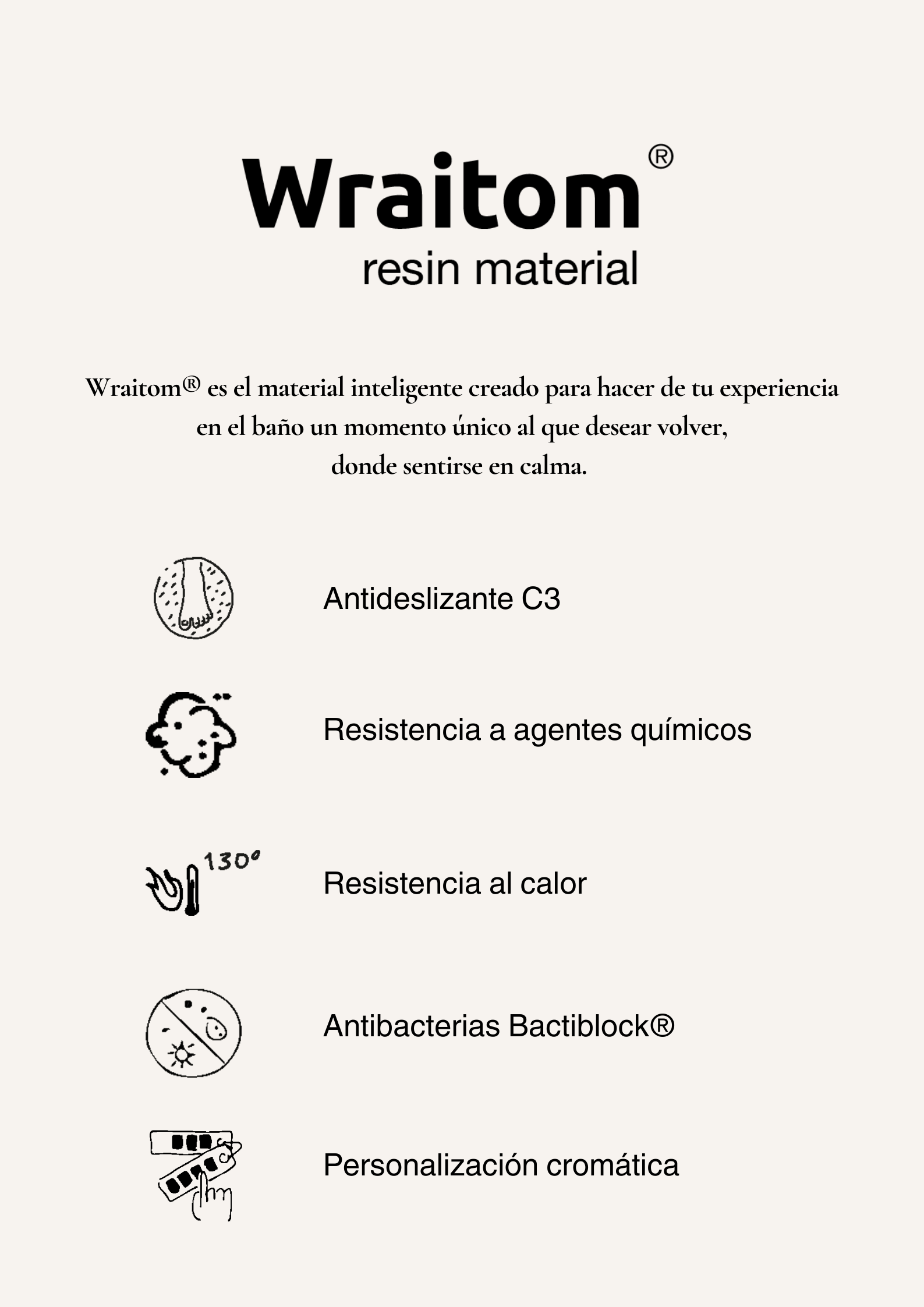

Designed to provide care and well-being, Wraitom®️ is an anti-slip and anti-bacterial material designed to guarantee the best care in the bathroom.

This material achieves a homogeneous and resistant mass thanks to its composition of mineral charges agglutinated with high-strength technical resins. Its main component is dolomite stone, which has been improved and prepared in different granulometries to offer the best performance.

The surface of Wraitom®️ is formulated with a sanitary Gel Coat that leaves no room for the appearance of possible bacteria and all the collections have the antimicrobial additive Bactiblock®️. This NBM patented technology is based on silver-functionalised clay, which is a highly effective natural source of antimicrobial agent. This additive inhibits the growth of bacteria, fungi and yeasts, making it a highly effective tool against odours and stains.

This material also allows colour customisation thanks to our Colorplus system, which makes it possible to create unique designs. For the most modern and original bathrooms, Wraitom® is the perfect choice.

The surface treatment of our shower trays avoids problems such as hydrolysis in the medium and long term, while exceeding all the requirements of the UNE-en 14527 standard and thus obtaining the CE marking for our products.Wraitom®️ guarantees a highly resistant, antibacterial, U.V. treated, pore-free and sanitary isophthalic product.

The variety of textures and designs offered by our Shile, Clay, Gneis and Hos's shower tray collections will allow you to choose the best rest for your feet. While in the Litos, Silea, Kila and Panela washbasin collections you will find the most original and functional designs to choose the one that best suits you.

Wraitom®️ is our smart material for the Bathroom line.

Its formula based on mineral fillers, high quality technical resins and Gel Coat surface finish make it an ideal material for bathroom requirements.

Sanitary Gel Coat is a material that covers the surface of shower trays and bathroom sinks and provides high technical, anti-bacterial and hydrolysis properties. This Gel Coat is highly resistant, non-porous, anti-ageing thanks to its UV and anti-bacterial treatment. The Gel Coat is sprayed onto the mould as the first step in the manufacturing process and is a differentiating element compared to other products on the market.

Once the Gel Coat has solidified in the mould, the resin-based mass and mineral filler are injected. Dolomite is used in different granulometries to generate a compact and resistant mass.

It also incorporates an additive that keeps the mineral filler in suspension during the hardening process of the shower tray, so that the particles are distributed in a totally homogeneous way, generating a compact and highly stable product.

When the mixture is injected into the mould, a thermal reaction begins which causes the resin and mineral mass to melt with the Gel Coat layer. A hardening process is generated and the product is formed as a solid piece.